Ipê Lumber Supply is in a Slow Motion Collapse

Why is the Ipê Market so Volatile?

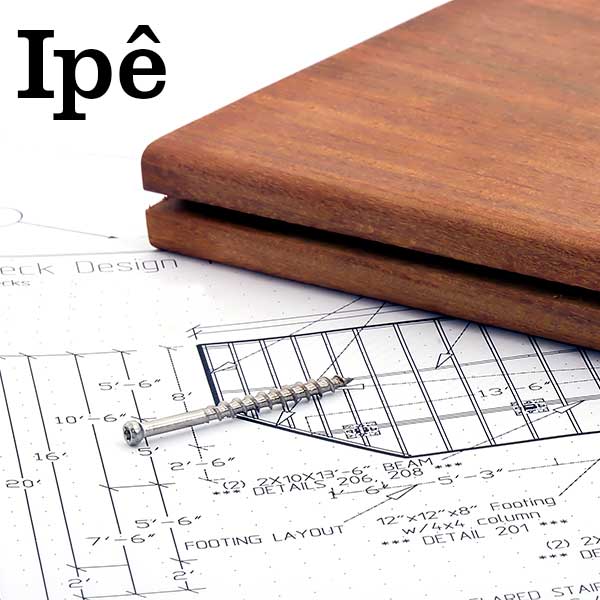

Ipê, (Português ), has long been regarded as the gold standard of hardwoods and for good reason. This uniquely dense wood provides an unparalleled level of durability against mold, insects, and fire with its unmistakable look that was once revered internationally by architects and designers alike.

Unfortunately, these benefits come at an increasingly steep price, and Ipê has never been more expensive or difficult to find than today. In fact, many builders across the country have been forced to put their projects on hold until inventory is replenished, with no guarantee that prices will not continue to increase in the near future.

Ipê also comes at an ever increasing environmental price, contributing significantly to the destruction of the Amazon. These impacts have led to many eco-conscious designers and architects eliminating its use completely, opting for a new generation of bamboo-based hardwood alternatives. These hardwood replacements boast the same fire resistance, beauty, and resilience of Ipê with superior ease of use, dimensional stability, durability, and environmental sustainability.

With the future of Ipê in jeopardy, we have outlined the top reasons the Ipê supply chain is in near collapse, and what can be done about it.

1. Ipê is an Outstanding Wood

Ipê’s has become a staple of high-end construction in the last decade for a very good reason- few other woods can match many of its unique qualities. Taking the place of increasingly hard-to-find Redwoods in the 1980s, Ipê has seen a meteoric rise in popularity since, with demand growing as much as 80% in 2021 alone, according to one Ipê importer.

Key to the wood's desirability is its density with a hardness nearly 9x that of second growth Redwood. In fact, Ipê is so hard that it can not be nailed through with a conventional hammer - requiring a notched tongue and groove fastening system in most cases.

The wood’s unique low resin and high polyphenol composition also give it a resilient sealed-like quality that makes it nearly impenetrable to biological elements. Being so dense, the boards absorb only minimal amounts of moisture, making them relatively stable through extreme temperature fluctuations with minimal warping or cracking. Ipê also provides superb fire resistance and pest resistance, particularly against termites that love chewing through softer woods, even when covered with resin.

|

|

|

|---|---|---|

| Flowering Ipê Tree in Field | Ipê wood grain at magnification | Ipê wood cross section at magnification |

2. Ipê is Rare and Slow to Grow

Ipê is a general term used for a variety of nearly 106 tropical hardwoods growing throughout Latin America, with the vast majority (96%) of global exports coming from Brazil to the USA and Europe.

Despite being widespread across Latin America, the Ipê does not appear in high densities. In fact, on average, one must scour 7-25 acres of Amazonian rainforest to find a single mature tree.* This scarcity is due in part to the Ipê’s winged seed that can easily be caught by undergrowth and makes for easy fodder for jungle herbivores. Once sprouted, the Ipê requires a sun-lit gap in the forest canopy open long enough for this slow grower to exploit--a challenging task in the deep rainforest.

|

|

|

|---|---|---|

| Ipê Seed Pod | Ipê Tree Silhouette | Ipê Flower & Seed Pods |

Once a sapling, the Ipê is extraordinarily slow growing, typically adding just 0.5-0.7 cm per year to its trunk’s diameter. At that rate, a typical Ipê tree requires 90 years to mature into a harvest ready size, significantly longer than a plantation pine (10-15 years), or typical oak tree (30-40 years).

Due to decades of exploitation across South America, CITES (The Convention on International Trade in Endangered Species) is now considering new protections for Ipê around the globe, potentially restricting global trade. This would not be the first time CITES passed a legislation to protect endangered hardwoods. Both Mahogany and some species of Teak were placed under protection leading to massive shifts in the lumber market in the 2000s.

3. Ipê Harvesting is Terrible for the Rainforest

Due to its long reproductive cycle, nearly all Ipê is harvested from the rainforest itself, rather than plantations. Given that the trees have been felled over many decades, the remaining trees are spread out through increasingly remote areas of the forest. As loggers reach deeper into the Amazon, the environmental cost of doing business continues to grow too, with untold acres of old growth rainforest cut clear to gain access at great environmental cost. (Both Peru and Venezuela have already declared Ipê a protected species.)

Some legitimate Ipê producers attempt to reduce their harm by implementing low-impact logging techniques which include targeting individual trees and replacing them with a sapling after harvest. The problem is saplings are in no way guaranteed to survive, particularly given Ipê’s unique light and water requirements in the rainforest. Worse yet, the process of extricating a single tree from deep within a tropical rainforest requires the creation of many roads and the disruption of natural habitat- often for the sake of a few logs.

Illegal Ipê logging is also a significant problem. According to the International Union for Conservation of Nature (IUCN) “Potentially high levels of illegal harvest have been reported in the country (Brazil), and there are concerns over inappropriate management measures including overestimation of sustainable offtakes.”

4. Ipê Harvesting is Naturally Expensive and Wasteful

The harvesting of Ipê also runs into a significant natural challenge every year that threatens its availability and increases its price - the tropic’s rainy season. These seasonal monsoons restrict the activities of loggers, sawmills, and exporters to just 5 months of the year, greatly reducing lumber producer’s ability to adjust to the demand.

The Ipê logging process is also pitifully inefficient; a 2018 study by the International Union for Conservation of Nature (IUCN) put Ipê’s processing efficiency at 42%, meaning that the majority of every tree is wasted. We suspect this is likely due to the tree’s density, which makes it difficult to laminate smaller pieces into larger boards using adhesives.

Once th jobsite, Ipê is a particularly difficult wood to work with, further increasing its price. It’s unparalleled hardness is infamous for eating away at saw blades, and requires contractors to take extra steps to utilize, such as pre-drilling holes and using cutlass fasteners.

Given the challenges of finding and extracting this wood from the rainforest and its difficulty of use, it’s safe to say there would be no global demand for Ipê if not for its exceptional properties as a hardwood, which until recently were unique.

5.Ipê Demand has never been Higher

Unfortunately, harvesting Ipê is inherently expensive, wasteful, and environmentally destructive, but that’s not all that’s driving Ipê to record high prices.

Demand for Ipê has grown as much as +80% in 2021 alone, reports one vendor, mainly due to America’s surging real estate market and Covid-inspired home renovations. Despite nearly doubling price in one year, Ipê producers will likely struggle to meet market demand due in part to the 7 months of rain every year that makes logging operations unable to expand to meet the demands of the market.

With ever scarcer supply, and unprecedented interest, there’s little reason to believe Ipê hardwood will become cheaper going forward.

6. Covid created Massive Capital and Supply Chain Problems

Covid has hit the world economy hard, and few places more so than in the Amazon. Due to the “lack of effective mitigation” Covid spread rapidly through Brazil’s Amazonian states, where weak public health infrastructure left the population exposed. This crisis led to a crippling of Brazil's lumber industry, causing many mills to go out of business.

A report prepared for the United Nations Forum on Forests Secretariat in late 2020 commented on the plight of lumber processors, stating “Stagnation of production, falling demand, scarcity of raw materials, lack of working capital, increase in freight rates and labor shortages, has forced many companies (e.g.paper mills, sawmills, wood product manufacturers and logging companies) to stop activities, in some cases permanently.”

Even with the growing price of Ipê, many tropical lumber mills will likely find it difficult to attract fresh capital to reboot operations given the insecurity of future harvestable lumber, and potential global restrictions from CITES on the horizon.

Indeed, even if the global economy were to return to “normal”, Covid’s damage to the industry may be intractable. With harvestable Ipê becoming more and more difficult to find, and cost-effective carbon neutral hardwood alternatives gaining popularity, it’s questionable whether these closed mills and processors will ever be able to find the capital needed to reopen operations.

7. Ipê Quality is Declining

Beyond Ipê’s rising price and collapsing supply, the very qualities of Ipê that make it remarkable are now under threat.

Despite sharing the same name, not all Ipê lumber is of the same quality, a fact that has become increasingly evident as second growth Ipê has become the predominant variety available within the US. Largely gone is the old growth that once had lumber importers in the 1990s promoting Ipê as “Brazilian Walnut” for its distinctive dark grain. Modern Ipê is much less consistent in color and is more disposed to warping, a trend that will likely continue as loggers target smaller and less ideal trees to meet demand.

Further jeopardizing future Ipê’s potential quality is the reality of global trade from the Amazon. At the time of writing, untold containers of Ipê hardwood are sitting off the coast awaiting arrival in a humid maritime environment, which may have negative consequences for the quality of the wood. Conditioned Ipê requires a 4-8% atmospheric humidity to maintain dimensional stability - and crossing that threshold will likely not be apparent to the end consumer, but could make for problems down the road as these boards warp more than expected..

Bamboo Hardwood Alternatives Replacing Ipê and Other Hardwoods?

(An example of an Moso Bamboo X-treme® Outdoor Decking and Siding, an eco-friendly replacement for Ipê, utilized here for a villa in Burgos, Spain )

In recent years, Ipê has found real competition from a new generation of thermal density treated bamboo-based hardwood alternatives that boast the same fire resistance, beauty, and resilience of Ipê with superior ease of use, dimensional stability, durability, and environmental sustainability.

Laminated bamboo flooring of the past was as much resin as it was bamboo, and was liable to easily warp with moderate swings in temperature and moisture. Now, thanks to a number of breakthroughs in natural composite technology, superior options, that are created by placing bamboo fiber under extreme heat and pressure, are now available. These forces fuse the lignin within the bamboo to create a natural resin harder than nearly any other wood on the planet resulting in a product 25% harder than Ipê. In contrast to harvesting Amazonian Ipê, this process sequesters a substantial amount of CO2 and is completely renewable and scalable, allowing it to scale to meet future demand.

One such competitor, MOSO®, (sold via Product Direct) has gained significant adoption of its high-density decking and siding throughout the last decade. Having become a favorite of architects and high-end developers throughout Europe, MOSO® Bamboo recently expanded into North America, and is in negotiations with major lumber retailers to expand the distribution of its compressed bamboo hardwood replacements.

With an estimated price point that is 30% lower than Ipê, MOSO® is poised to potentially undercut the Ipê market in the near future, particularly as Ipê supplies continue to fluctuate in price and availability.

The Future of Ipê

Put simply, Ipê’s main challenge is sustainability - both environmental and economic. With the Amazon's easily accessible reserves tapped, and supply chain issues exacerbated with Covid, the cost of Ipê is not expected to drop any time soon.

Even in the most optimistic of analyses, Ipê lumber will not be able to meet its global demand in the coming years due to the 70+ years required to propagate new stock. With more competition than ever in the hardwood market from sustainable alternatives that boast the same beauty and performance at a lower cost, it’s hard to imagine a future where Ipê is the material of choice for builders and homeowners looking for premium decking and sighting options.