Buying a floor

In keeping with our effort to Keep It Simple, we have compiled a one page summary of all things related to wood flooring. This is not meant to be a complete read, but more like a guide to help you make some fundamental decisions and focus more on the look and feel that you are after.

What is Hardwood?

If you are new to hardwoods and flooring, this article is a short description that may help you clear up some points. The word hardwood refers to a wide grouping of trees that can grow in temperate, subtropical and tropical environments. What makes these trees appealing for placement as floors is the density of fibers in the tree trunk and branches themselves. When a hardwood beam is milled down to a floor plank vertical lines with intricate grains can be seen running up and down the length of the plank. High density fibers are more desirable; low density fiber are less desirable. In general, hardwood trees grow slower which contributes to a higher fiber density and toughness of wood. A higher fiber density also contributes to greater difficulty in processing timbers making them more expensive to reproduce, harvest and mill.

Hardwood trees in general make good floors because they have a high resistance to wear yet maintain a visually appealing quality to them for the lifetime of the floor. They add lasting value to the home. In contrast softwoods have a lower fiber density displayed as a lower grain density. This translates into a floor that is less resistant to abrasion and may not support as long a floor life as it is more susceptible to scuffing and denting.

Ways to View Your Hardwood Options in Your Home

| If You Own a Traditional Home | If You Own a Country Home | If You Own a Modern Home |

|---|---|---|

| Warm, elegant floors are often found in traditional American homes, such as Colonial and Georgian style houses. Suggested woods for a traditional architecture include: Traditional Home features elegant decorating and interior design, plus ideas for dreamy gardens, gracious entertaining, collecting art and antiques, and more. | The country look has held a special place in American architecture for many years. It remains the single most popular style for American homes (Rosch, 2002). Early settlers mixed influences of Old World architecture with hand-hewn tools and materials available in the American frontier. The result was a blend of the beautiful and the practical. | Contemporary design or modern design relies on clean lines, smooth and polished surfaces, and few intricate details. It is not stark and cold, but contemporary design is comfortable and spacious, without clutter. Contemporary design focuses on neutral colors, such as creams, whites, browns, blacks and taupe. Bold colors, such as red or yellow, are for accent. |

|

Eastern White Pine It is a fine, smooth-grained, knotty wood, with a very soft texture. It is very authentic for older homes, creating a warm, classic tone. Cherry A subtle, tight grain, medium hardness, and a deep red color are the hallmarks of cherry flooring. The red color of cherry continues to deepen over the years, resulting in a warmth of tone that is almost unmatched. A cherry wood floor works well in formal or country settings. White Oak A tight-grained, dense, hard wood. A white oak wood floor is seen in many classic American homes. The select grade gives a more traditional look, while country grade white oak, more knotty in appearance, can be used to create a more rustic looking wood floor. Heart Pine One of the best-loved of all American woods. A heart pine wood floor is another time-tested American look. It is a very hard wood with a dramatic, flame-like grain, and an orange pumpkin color. It works beautifully in a country or a traditional setting. |

Heart Pine The classic heart pine wood floor looks as good in a country setting as it does in a traditional one. For a country, or rustic wood floor, wide plank heart pine is a perfect choice, with its flame-like grain and color like a pumpkin. Eastern White Pine The smooth-grained, knotty, eastern white pine creates a wood floor that will look right at home in a country style house. It has been the wood of choice in American country homes for generations. Character Grade White Oak For a more rustic looking wood floor, the flecked pattern of character grade white oak, very suitable for quarter-sawn flooring, is an excellent choice. Red Oak Coarse-grained, quarter-sawn, wide plank red oak flooring creates a timeless country look that will enhance any country style home. |

Hard Maple This durable wood has a tight, close grain, and is one of the hardest woods available. Hard maple flooring has a clear, light look, and is perfect for light, contemporary rooms with plenty of windows. You will see hard maple used in settings that require an extremely hard-wearing surface, such as a gymnasium. Birch Another hard-wearing, dense wood, birch has a tight grain, and a subtle, sometimes swirling pattern. Birch is the perfect wood for a modern, light floor. Hickory A very hard, tight grain, usually with some knots, and sometimes the grain can be dramatic. A hickory floor can work just as well in a country setting as in a modern one. Walnut A popular choice, walnut is medium-hard, with marbleized coloring, and well-suited to natural finishes. Walnut flooring is a very versatile wood, suitable for many architectural styles. |

-

Unfinished Hardwood

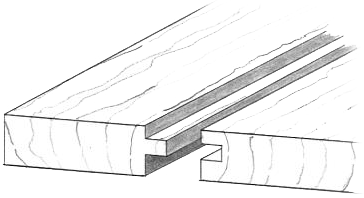

The original hardwood floor consisted of placing milled planks on supporting rafters such that they lined up to form a smooth plan. Tongue and Groove was the method most familiar to the craftsman that placed the planks on the floor.

- Once fastened to the floor side by side

- Sanded to make a smooth surface

- Stained with a color that is aesthetically pleasing

- Sealed with clear coat

- Buffed and polished as desirable

This entire process can take weeks. It also required clear wood that is free of knots and imperfections to pull it off. All in all it has a labor price that puts it out of reach of almost all, and certainly is not practical in light of alternatives available on the market.

You notice as you look at floors that planks placed together have a slight bevel in the seam where they meet. This is done to eliminate splintering of the edges during installation and use after installation. Old school unfinished floors may have square edges which is suitable if you are sanding the planks after placement. Modern pre-finished floors almost universally have a slight bevel on the plank edges. Laminate Floors can be found either way.

Bevels

How to think about hardwood

A reliable indicator of prefinished wood's resistance to abrasion and overall lifetime wear is to look at the hardness of the wood itself. Wood hardness is expressed as its resistance to denting. It has a formal method of discovery covered under the Janka Scale. In General, suffice it to say the harder the wood the longer the floor will not suffer catastrophic marking. This must be viewed in combination with the coatings on the surface which predict the resistance to abrasion.

Take-aways

You have options of color, plank width, and clearness of wood and surface sealers. Plank corner edges may be slightly milled so as to create a bevel. Lifespan anywhere from 80 to over 100 years. Due to its thickness, it can span slight differences in sub floor height without flexing when walked on. These edges produce a good solid floor structurally and are usually available in longer lengths than engineered flooring. This plank is usually less expensive than a high end engineered flooring. It can be sanded and refinished multiple times if needed. Hardwood flooring is the only floor covering that increases the value of your home. Hardwood flooring does not cause allergies, and is routinely recommended by allergists.

Watch-outs

Extremely time consuming and labor intensive; the sanding, staining and coating process can delay projects. Generates a lot of dust during the sanding step and a lot of solvent vapors during the sealer phase.The finish coat is almost always softer than a prefinished floor that is baked on at the factory.

Prefinished Solid Hardwood

Prefinished Hardwood is a huge improvement in wood flooring; a godsend for labor reduction as it installs right out of the box. Prefinish means it has been milled to a smooth ready-to-use surface, stained to the required color, and coated with a hardened sealer; usually an Aluminum Oxide polyurethane base provides optimum surface resistance to abrasion.

A tree is a natural product subject to natural variations. Among the most important variation is the number of wood knots in the wood. Less knots means a clearer wood; clear wood is more expensive. More knots, more expensive. Below is a grouping of "Grade" Classifications in discussing wood.

Hardwood Grades

| Prefinished | Unfinished |

|

Clear Grade - Is the very best hardwood flooring grade which has the most uniform color, longer lengths, virtually no blemishes or knots. Select & Better - Is the next best wood flooring grade with uniform color, longer lengths virtually no blemishes or knots. Select or Exclusive Grades - Boards starting to show the natural character such as lighter and darker boards, may have shorter board lengths, infrequent small pinholes and tiny knots possible. Traditional, Antique, Character Grades - Boards show a lot of natural character such as light and dark boards, pinholes and knots possible, small checks allowed. Overall board lengths are shorter depending on style manufactured. Tavern or Cabin Grade - Lower costing Hardwood Flooring that can show a lot of character such as light and dark boards, lengths of boards are shorter approx 24" average. Pinholes and knots can be quite evident. |

Clear Grade - Is the very best hardwood flooring grade with the most uniform color, longer, lengths, virtually no blemishes or knots. Select & Better - Is the next best wood flooring grade, very uniform color, longer lengths, virtually no blemishes or knots. #1 Common - boards starting to show the natural character such as lighter and darker boards, shorter board average, pinholes and knots are present. #2 Common or rustic grade- boards show a lot of natural character such as light and dark boards, larger knots and checks allowed. Over all board lengths are shorter. Utility grade or Shorts - boards show a lot of natural character such as light and dark boards, lengths of boards are extremely short approx 16" average, knots and pinholes are quite evident. |

Take-aways

Hardness and surface coatings will predict the life of a floor. Staining in combination with tree species will provide the final display color in the room.

Watch-outs

Hardness must be balanced with expense and aesthetics. All woods will fade in direct sunlight, Lighter colors may be a better pick in areas that get a lot of sunlight.

Prefinished Hardwood Engineered

Engineered Hardwood floors are constructed with 3-12 multiple ply layers that are cross layered, glued and pressed together much like a sheet of plywood. The lower layers are are generally built up with either a hardwood and/or soft plywood type of material, which incorporates the tongue and groove system. The top thicker hardwood veneer wear layer is then glued and pressed on the top surface of the core. Engineered hardwood flooring is available in almost any wood species.

Plank widths range from 3-7 inches wide and can be had in thicknesses from 3/8 - 3/4".

Take-aways

This floor is more resistant to higher moisture levels than solid wood flooring, which adds to their appeal to use in damp basements or in regions of the country that have higher relative humidity levels. Also, engineered flooring (excluding the newer Click Lock flooring) can be direct glued-down over (dry) concrete slabs above or below grade or stapled down over a wood sub floor. Engineered Hardwood flooring of good quality has a similar resale value as solid wood flooring, if you ever decide to sell your home.

Watch-outs

Some brands of engineered flooring have a thin .6 millimeter wear layer that can only be re-coated and cannot be sanded and refinished new again once they get worn. They have an average lifespan of between 20-30 years depending on traffic. Other brands or styles can have a thicker 2 - 6 millimeter thick wear layer that can be completely sanded and refinished 1- 5 times if they ever needed to be. These thicker wear layer engineered floors can last from 40 - 80 years before having to be replaced which add to their appeal.

What is a Quality Hardwood Floor?

Quality is simply defined as conformance to requirements. Your aesthetic requirements in combination with the use under load requirements will determine how much to spend. Basements get a different look and wear than a Great Room in a Traditional home. You may want to showcase your taste and flair for decorating and spend on the aesthetics of a clear durable lustrous hardwood. Or you may not care too much about looks and do not want to touch your floor again for the lifetime of your investment. In this case, something much less expensive will meet your requirements. It is a balance between aesthetics, purchase & installation cost

Laminate Hardwood Flooring

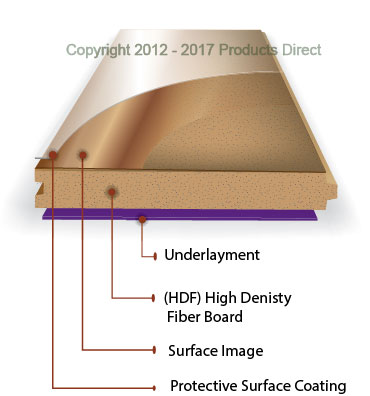

Laminate flooring reduces the cost of flooring by using a photograph of the floor instead of the real wood or tile itself. The surface image can be of an expensive hardwood or a beautiful ceramic tile. The image is united with several layers. Below the image surface is a thick board like high density fiberboard(HDF). To protect the surface image, a protective coating is applied on top to the mounted image. This coating is a hardened chemical coating made form polyurethane that has been cured(hardened). This is the coating that gives the product a real luster and its resistance to abrasion of the top surface and to the image below the surface.

An underlayment padding is recommended and may be part of the board. In other cases during the installation process, you may have to put down padding first. Underlayment already glued to the board is a time saver.

Abrasion is the enemy of this type of floor. Laminate Flooring's resistance to abrasion is given as its abrasion class, commonly referred to as a "AC Wear Rating" "AC" stands for "Abrasion Coefficient" The rate of abrasion resistance is established in what is known as a "Taber" test and is assigned classes according to the Euro Standard EN13329. The abrasion class is determined by clamping a sample piece in a testing device and placing friction wheels covered with emery paper on the sample piece. The piece is checked for abrasion after every 100 revolutions. The emery paper on the friction wheel is changed every 200 revolutions. The initial abrasion point (IP) is the point at which clearly detectable wearing through of the decorative print occurs for the first time.

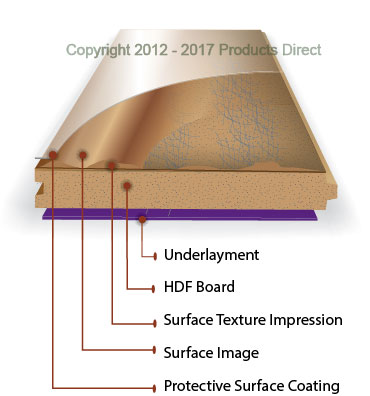

Textured Laminate Hardwood Flooring

Textured surfaces give the real life like look and feels of distressed wood or hand scraped wood floors. This feature makes the floor appear more life like. This is an aesthetic option to the flooring decision process. The texture is mechanically created during the manufacturing process so as to alter the smooth surface of the base HDF board resulting in wavy boards or jagged irregular edges. This step adds more cost to the laminated floor but gets the room look closer to seasoned hardwood floor without blowing the budget.

Labor time required to install a laminate floor is less than that of hardwood floors. The image of multiple strips of hardwood give the impression of multiple strips but the plank width is often larger making is possible to install a floor and putting down fewer pieces.

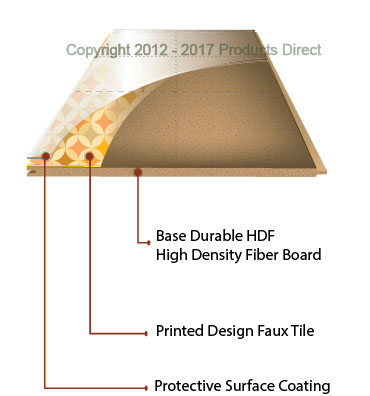

Laminate Tile Flooring

Tile laminate flooring reduces the cost of real tile by using a photograph of the floor instead of the real wood or tile itself. The surface image can be of an expensive hardwood or a beautiful ceramic tile. The image is united with several layers. Below the image surface is a thick board like high density fiberboard(HDF). To protect the surface image, a protective coating is applied on top to the mounted image. A hardened chemical coating made from polyurethane that has been cured(hardened). This is the coating that gives the product a real gloss and its resistance to abrasion of the top surface and to the image below the surface.

Usually tile laminate flooring has surface contours that resemble the actual tile grout seams. These contour impressions are in the underlying HDF board and give the product a very realistic appearance. An underlayment padding is recommended and may be part of the board. In other cases during the installation process you may have to put down padding first. Underlayment already glued to the board is a time saver.

Laminate Quality Considerations

Flooring Warranty Statements Backed by Abraser Testing

How long a laminate floor will last depends upon the product selected, the amount of traffic, and how well the product is cared for. Based on requirements like the Taber test, consumers can be assured that their laminate flooring will withstand many years of use. [Note: It is important to recognize that most product warranties do not cover abnormal wear and tear resulting from damage caused from spike heel shoes, insufficient protection from furniture, and other abrasive materials such as loose sand.]

The appearance of laminate flooring is based on the decorative layer, which is actually a high-resolution picture. To give the product its durability, the top layer of most laminate flooring is made from melamine resin - a highly wear resistant material. Although laminate flooring is very durable, when the wear layer is worn through by excessive foot traffic or other means damage may occur to the decorative layer.

All reputable manufacturers of laminate flooring adhere to internationally recognized test standards that describe a variety of procedures used to evaluate physical properties of the product. To determine how much "normal" wear and tear the product can hold up to, flooring manufacturers use the Taber Rotary Platform Abraser. The Taber test measures the number of wear cycles completed until initial damage to the decorative layer is observed, providing an indication of abrasion resistance characteristics. This accelerated test allows the many years of wear to be compressed into a very short duration.

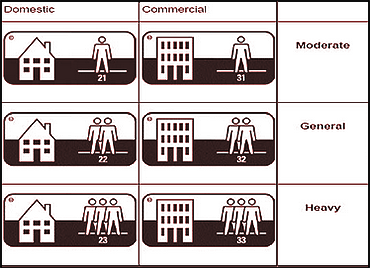

Using a rating scale, the laminate flooring producer can determine which classification the laminate floor satisfies and to what market segment it should be promoted. As the total number of Taber wear cycles increases, so does the product's durability. As an example, the AC rating is often referenced:

- AC1 Moderate Residential: Intended for infrequent traffic and light residential use (i.e. bedroom)

- AC2 General Residential: Able to handle moderate foot traffic for most residential spaces (i.e. living room or dining room)

- AC3 Heavy Residential/Moderate Commercial: Can be applied to more varied locations, including high-traffic rooms and commercial spaces with light traffic (i.e. small offices)

- AC4 General Commercial: Suitable for all residential uses as well as more heavily trafficked commercial areas (i.e. offices, restaurants, and boutiques)

- AC5 Heavy Commercial: Recommended for commercial use in high–traffic spaces (i.e. department stores and public buildings)

Hardwood & Laminate Alternatives: Bamboo

Bamboo is one or nature's most eco-friendly resources, Most bamboo floors are made from the Moso species of bamboo and only harvested from plantations or managed forests in the tropical mountain regions of China and southeast Asia. Moso Bamboo is a temperate species of giant timber bamboo native to China. Moso bamboo is only suitable for flooring once it reaches 5½-6 years of maturity. This bamboo can reach heights of up to 92 feet in height.

Flooring made from Bamboo is an excellent choice for a floor because it is a durable floor, aesthetically pleasing and ecologically sound. The manufacturing process results in several varieties of floor.

Bamboo Colors

- Natural Colored floor looks blond yellow in color and can show the grain of the shoots.

- Spice color is the same as Carbonized color. This color tone is a darker version of the normal blonde bamboo color. Most people are used to the light, almost white color of natural bamboo wood. While this is a beautiful shade, it is also possible to darken bamboo wood through steaming. Bamboo carries a lot of sugar, so when manufacturers cook the bamboo stalks in a steam bath, the sugar to breaks down and darkens just like regular sugar does when heated for a recipe. The end result is bamboo the color of caramel. The main reason people opt for carbonized bamboo over typical bamboo is the color. Natural bamboo has a very light finish, while carbonized bamboo is much darker. The biggest disadvantage, however, is that the carbonizing process slightly weakens bamboo, making it a somewhat softer wood that is more prone to scratches, dings, and wear.

- Other versions of colors can be obtained using a stain. to give variations of color from pale gray to deep red.

- Strand Woven has its own unique quality of light and dark spaces on the same floor.

Bamboo Vertical - Solid

Bamboo Vertical references the construction of the plank. The diagram to the left shows how the individual strands are placed side-by-side short edge to the surface of the plank. This gives a tight strip pattern to each plank. The surface is sanded smooth and a tough protective surface coating is applied. Due to the nature of bamboo the planks can be up to 6 feet in length with widths from 3 - 7 inches. This thickness of the vertical plank is usually about the same as the thickness of the horizontal plank construction. Both are durable and have similar warranties. The main reason to choose one or the other is aesthetics.

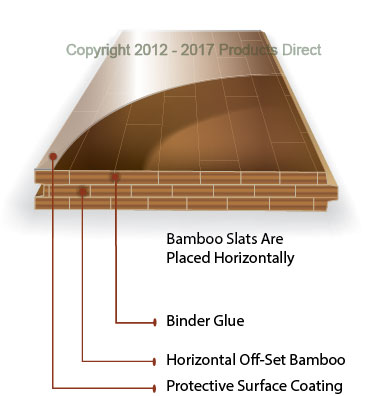

Bamboo Horizontal - Solid Floor

Bamboo Horizontal references the construction of the plank. The diagram to the left shows how the individual strands are placed side-by-side long edge to the surface of the plank. This gives a wide strip pattern to each plank. The surface is sanded smooth and a tough protective surface coating is applied. Due to the nature of bamboo the planks can be up to 6 feet in length with widths from 3 - 7 inches. This thickness of the horizontal plank is usually about the same as the thickness of the vertical plank construction. Both are durable and have similar warranties. The main reason to choose one or the other is aesthetics.

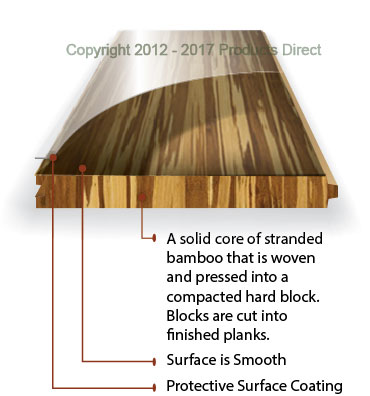

Bamboo Strand Woven - Solid Floor

Stand woven refers to the manufacturing process that yields the planks used to make the floor. This floor can have a unique presentation of dark and light colors that make a dramatic statement. In this case the floor is made through combining carbonized and non carbonized bamboo strands in a mechanical process that shreds and compresses the strands into one block bamboo. Strand woven can also be comprised of similiar color strands for a more uniform color.

Strand Woven in the Production Process

These strand woven blocks are cut into planks much like a large block of wood is cut into planks. These planks are then refined and a protective surface coating is applied.

Strand woven is harder, i.e. dent resistant, and more stable, i.e. measured resistance of the wood to environmental changes such as moisture or temperature than most hardwoods.

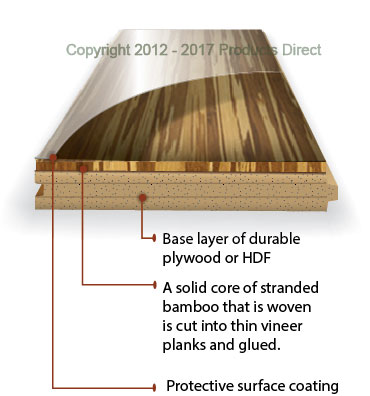

Bamboo / Strand Woven - Engineered Floor

To reduce the cost of bamboo flooring the strand woven bamboo is cut into thinner slices and glued like a thick veneer to a engineered board made of robust plywood underlayment. The economical value is that thinner slices of strand woven bamboo makes for a lower cost floor.

Cork Floors

Cork is comprised of millions of tiny air cells making it naturally resilient and comfortable underfoot. The unique cellular structure makes cork a superb sound and thermal insulator. Cork is ideal because it is not destructive to the tree to harvest the bark. No trees are cut down to harvest the bark. Cork trees produce new cork for re-harvest every 9 years.

The floor has a similar construction to other engineered floors. The cork medium is manufactured to precise specifications for color and quality. The Cork is attached to a moisture resistant HDF core. Depending on the product an underlayment may be attached eliminating the need for a separate step in the installation process.

A protective UV-Cured coating is applied that offers advanced abrasion resistance, slip resistance and protection against fading due to sunlight. Cork is produced in a variety of textures depending on the density of cork and color.

How To Choose Bamboo Versus Hardwood Versus Cork

Practical Decisions

When purchasing bamboo flooring, you must first decide if you like the visual appearance of horizontal, vertical or strand woven bamboo. Strand woven is by far the toughest most scratch and stain resistant. Bamboo is 27% harder than oak and 13% harder than maple. While solid hardwood may not be installed below grade, a strand woven engineered bamboo would be a nice alternative to solid hardwood and can be installed below grade.

Aesthetic Decisions

Natural Bamboo contains differences in tone and appearance. These variations establish the unique character found only in Natural Bamboo. If you wish to go for a stained bamboo that has a darker appearance there will be less color and tone variation than in the Natural Bamboo.

Purchasing Molding & Transitions is Easy

Molding comes in many shapes sizes and colors. We have many items available to compliment your purchase. Since there are so many variables, we recommend that you contact us at call 1.888.735.6679 or email us at support@productsdirect.com with your requirements, and we will provide a firm quote.

Let us help you match up the perfect trim, moldings and baseboard for your new project. If you are new to flooring, here is an outline of the basics. There are 5 basic profiles that are used in the installation of a floor. In most cases, we can provide all of them.

- Quarter Round - used to cover the expansion gap between a floor and wall. Wall molding does the same task with the exception that it covers part of the wall as well.

- T–Molding used between the floor and another hard surface

- Thresholds Used in doorways as a transition between two different floor types

- Reducer Used to cover the gap in heights between flooring of two different thicknesses

- Stair Nose used to finish the edges for stairs and landings

Printable Check List

Proper Planning Makes an Excellent Start.

Checklists are an important way to get things done right. We have developed a simple checklist to help you be efficient in planing and executing your project.

Feel Free to download it and use.

Underlayment

Here are some of the typical reasons to use an underlayment

- Close Cell Technology, Best for Sound Absorption

- Waterproof Qualities

- Reduces Nosies Levels

- Insulates & Protects Floors

- Reduces Minor Sub-floor Imperfections

- Installation of Sub-floors

- Anti-Bacterial, Mold & Mildew Resistant.

Flooring Care

What To Do

- Vacuum or sweep floor regularly. General cleaning every 2 weeks is recommended.

- Remove spills promptly. Use protective pads or caps on "feet" of furniture.

- Place mats at exterior entries to catch sand and grit. Use area rugs in all high traffic paths, at the ends of steps and near doorways to outside elements. Avoid rubber backed or non-ventilated rugs.

- Maintain a consistent humidity level between seasons. Excessive swings in humidity levels will cause hardwood floors to swell, shrink, cup, crack and show excessive gaps between boards. The use of humidifier/dehumidifier systems is recommended where inconsistent humidity levels occur.

What Not To Do

- Don't let sand, dirt or grit build up on floors. This will act like sandpaper and actually abrade, distress and dull your floor finish.

- Don't wet mop hardwood floors. Don't flood floors. Often too much water can cause the floor to swell or warp.

- Don't let your pets' claws go untrimmed. Claw trimming avoids scratches and gouges in your flooring.

- Don't walk on hardwood floors in high heels, and keep heels in good repair. Stiletto heals can cause punctures in the flooring.

- Don't use wax, oil soap or other household cleaners on polyurethane finished wood floors. They can dull today's floor finishes and make refinishing difficult.

Are Floor Samples Available?

You are invited to order a sample or purchase a few planks to visualize if the flooring will go with your colors and decor? Our policy is to give you the sample but ask that you pay for shipping. You can give us a call at: 1.888.735.6679 or email us at support@productsdirect.com. You are also able to order samples directly from many of the flooring and trim product pages.

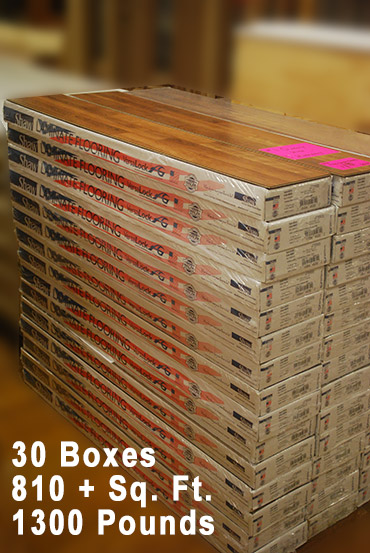

Shipping a Floor

Shipping a floor is not the same as shipping a book; but make no mistake it is done every day. The first thing to recognize is that this is a heavy load. The photograph to the left provides an important visual; 30 boxes of flooring, a typical home floor plan. Weighing in at over a half ton it just might break your car if you transport it yourself. We suggest you try a freight delivery to your door. The logistics of transportation are complex. Not all residential locations can receive freight trucks. Check with us and we will go to work for you and get your available options.

Considerations

As an online retailer we have expertise in shipping large purchases, and pallet loads of materials across great distances.

One thing we have learned is that shipping cost greatly affects the total delivered price of the product to your project. Correct shipping logistics can be a great time saver and move your project closer to completion faster.

We have relationships with many carriers. If you have a large order and want to see what our total delivered cost is give us a call at: 888.735.6679 or email us at support@productsdirect.com. You can also reach out to us by Live Chat.

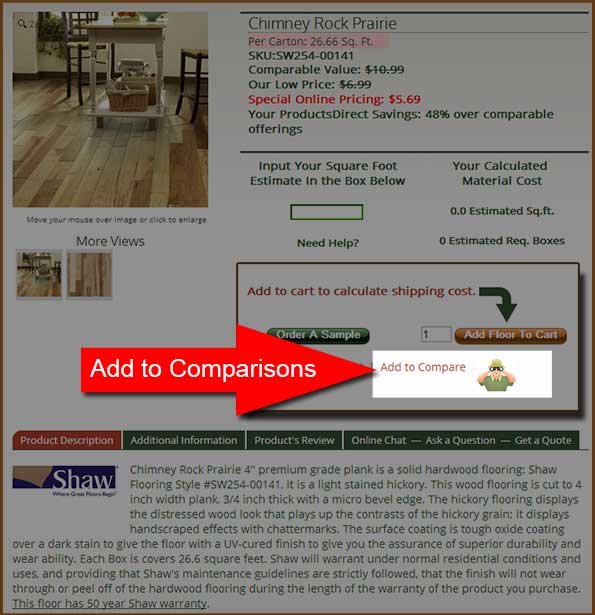

Getting Clear: Simplify the Buying Process!

Choosing a floor is daunting because there are so many variables. We simplify the buying process with the help of a comparative shopping feature on this web site.

On every flooring product page you will find an option to add the product to a comparison chart. Once you add to the comparison chart you can view the chart by clicking the search guy in the footer of the web site.

Product Viewing Page

Access the Comparison from the Page Footer

Flooring Chart Comparison Chart

Flooring Comparisons and what to think about

Are you headed to the store to buy flooring? Whether it is online shopping or brick and mortar, don't get overwhelmed, get answers. So much lies ahead, let us guide you through the process, as we are here to help you with that. The better you understand not just what you like but what your room needs, the better your flooring selection will be.

Think about room logistics:

- How do you use the room most?

- What types of activities are common in this room?

- What are the room's lighting sources?

- What is the size of the room?

- Does the room flow into others or stand alone?

Think about existing or intended aesthetics:

- How do you want to feel when you're in this room?

- What types of furnishings do you have?

- What's the style of the room?

- Traditional? Contemporary? Rustic?

- What's the feel of the room? Casual? Formal? Somewhere in between?

Consider risk factors for the room:

- Will people have food in this room?

- Will kids play in this room?

- Will kids play with their food in this room?

- Does the room directly open up to the outside?

- Do you have indoor pets?

Warranties

Most of the hardwood flooring that Products Direct® sells has a 15 to 50-years limited warranty. These warranties vary for different hardwood products. For more information on the specifics of these warranties, please contact us with your questions.

Residential versus Commercial Environments

Residential environments have lower wear-and-tear loads than commercial environments. Homes simply have less traffic than public venues. Commerical environments usually require a different specification of flooring manufacturing. It is a more robust specification and more expensive to make. Trying to cut the cost by installing a residential flooring in a commercial environment will not get the same floor performance. Manufacturers recognize this and will not warrant residential spec'd floors in commercial environments. You will often see this exclusion clause in warranties.

Structure Warranty

This category typically warrants that the covered products in their original manufactured condition will be free from defects in lamination and structure for as long as the original purchaser owns the floor in the event of failure in lamination or structure following approved installation methods within the first year of use.

Usual remedies includes an option to either repair or replace defective planks free of charge. If a failure occurs more than one year after installation, this area of the warranty usually states it will replace the defective plank(s) exclusive of the cost of removal, re-installation or refinishing.

Finish Wear-Through Warranty

This category typically warrants the original purchaser of covered products that for some amount of years the finish will not wear through under normal usage if proper care and maintenance guidelines are followed. Usually this warranty area extends only for wear through areas, which cover at least 10% of the floor surface area installed.

Resurfacing Warranty

Some manufacturers warrant that its residential flooring can be resurfaced by removing the existing finish and replacing it with an industry approved finish. Check the details, this section may require that an accredited wood flooring professional that is knowledgeable and proficient in refinishing techniques must perform this process. (Visit: www.nwfa.org for a list of professionals within your region).

Additional requirements spec out the amount of the existing wood surface that can be removed per re-surfacing. Usually manufacturers do not warrant coloration changes, dents, scratches and patina that come with normal use and appropriate maintenance of floor.

Warranty Exclusions

All manufacturers that offer warranties will not apply if the following situations are proven demonstrated to be true: Improper installation, improper maintenance, misuse, alterations of product, indentations, scratches or other damage caused by water erosion, insects or spiked heels of any sort.

Most manufacturers will not accept any claim resulting from non-compliance with recommendations supplied by them concerning the storage, job site conditions, installation, or general care and maintenance of the floor. Most manufacturers do not warrant against sun fading (sunlight effects all wood species as they age). Often the warranties become void upon sale or transfer of the installed product from one owner to another. For your warranty to be valid, you must have the original sales receipt and be the original owner of the floor. Warranty claims are processed directly through the manufacturer. Products Direct Inc.® can refer you to a phone number but we do not participate in the claim process.